Description

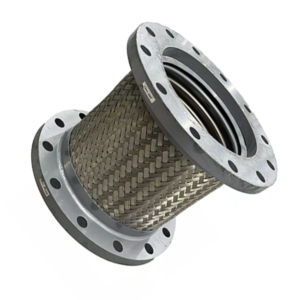

Main parts of the hose material is the use of austenitic stainless steel, thus ensuring that the hose excellent temperature resistance and corrosion resistance,

the hose working temperature range is extremely wide, for -196-600 ℃, the use of the hose according to the corrosive nature of the pipeline through the medium to select the applicable stainless steel grade, you can ensure that the corrosion resistance of the hose.

Features:

1. The whole metal hose is made of 1Cr18Ni9Ti stainless steel material, which has strong corrosion resistance.

2. The hose body is a thin-walled stainless steel tube body hydraulic molding, with strong flexibility, expansion and contraction, bending and vibration resistance, braided mesh sleeve to strengthen the protection, so that it has a higher pressure capacity.

3. The connection between the two ends of the hose can also be made in addition to threads, flange standards other than the connection, easy to connect and use.

4. The product is not only suitable for matching with rotary joints, but also widely used in a variety of fluid media transportation of soft connections.

Corrosion resistance, high temperature resistance, low temperature resistance (-196℃~+420℃), light weight, small volume, good flexibility. Widely used in aviation, aerospace, petroleum, chemical, metallurgy, electric power, paper, wood, textile, construction, medicine, food, tobacco, transportation and other industries.

1, Metal hose pitch between the flexible hose, bending radius is small.

2, Metal hose has good scalability, no blockage or stiffness.

3, Metal hose unit weight is light, caliber consistency is good.

4, Metal hose flexibility, repeated bending, good flexibility.

All isolators are pressure tested at the factory to ensure a tight installation.

These pump connectors are an economical solution for isolating vibration between equipment such as compressors and pumps and piping systems.